Precision mechanical machining for over 40 years

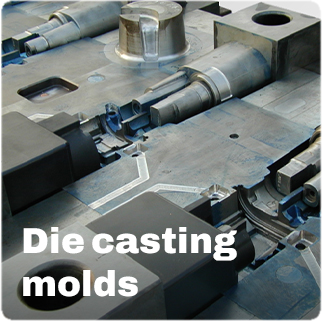

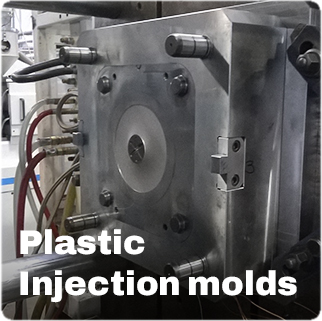

C.T. & T. was founded in 1979 by two partners with high skills in precision mechanical machining. Artisan reality, it takes its first steps in the production of thermoplastic molds, focusing mainly on the automotive and electromechanical industry. In its development, the company specializes in the design and manufacture of equipment and molds for aluminum, zamak and magnesium, die-casting up to 1.5 meters (60 quintals), which currently cover most of its production.

For us, each project is unique and for this reason we put our attention on the pre-sales service, that allows us to propose solutions that are fully integrated into the mass production equipment of our customers. Competence, technology, quality and passion for our work are the right mix to support our success in thedomestic and foreign markets.

Our numbers

square meters of production area

working centers in operation

maximum weight of the molds

years of activity

Our production process

1. Design

2. Flow analysis

3. Mold making

4. Sampling

5. Control

6. Maintenance

1. Design

Each phase of the project is shared with the customer

Design is a essential phase: we use our knowledge to find the best solutions for customer’s needs. Each project is created in close contact with the customer’s technical department and foundry department in order to create ad hoc solutions through the study of the most suitable materials and related mechanical solutions.

2. Flow analysis

We anticipate problems

The simulation comforts our choices and often intercepts any problems, otherwise highlighted only in the sampling phase. To ensure maximum efficiency and improve the productivity of our equipment, we have been collaborating with an external partner for over 10 years.

3. Mold making

Whether it is a high-volume mold for automotive industry, or one for small production batches, we provide all our technology.

The tool shop has 8 high-speed 3 /5-axis machining centers (CB. FERRARI-SECMU DIGMA-HURON-DECKEL – DMG MORI), 2 AGIE spark erosion and FANUC wire erosion. Column drills and lathes (SHAUBLIN) complete the machine park.

Recently the toolshop was implemented with a HS gantry milling machining able to work in roughing and finishing blocks up to 5ton with a table that reaches 1,7m x 1,3m.

The work centers are programmed by 4 CAD / CAM stations (cimatron-autom). Our equipment allows us to manage all the mold parts, on one’s own, leaving only the heat treatments to external, certified suppliers.

Finally, we have 2 complete stations for the assembly and adjustment of the mold.

Since 2018 we have implemented the company with “industry 4.0”: the new equipments are directly connected to ERP SYSTEM, to check the progress of the work.

4. Sampling and start-up assistance

Once made, we test the mold

We think it is essential to offer the sampling service of our equipment, both on die-casting molds and on thermoplastic molds. We are available to support you during the start-up of the mold.

5. Dimensional control

The last check before delivery

As a guarantee of our work, we use a CMM machine to check our dies parts , and perform dimensional checks of the samples produced by our molds.

6. Maintenance

Reliable partner for the entire life of the mold

For us at C.T.&T. it is essential to offer the customer an after-sales service that follows the life of the mold even outside the standard warranty.

Contact us for advice!

Do you want to be contacted by our staff to receive more information about our services? Fill in the following form.