Thermoplastic

injection Mold

Mold makers since 1979

From design to costruction

C.T. & T. designs and manufactures high quality and thermoplastic injection molds.

This is thanks to a state-of-the-art machine park and the know-how of an experienced and qualified team.

The stages of costruction

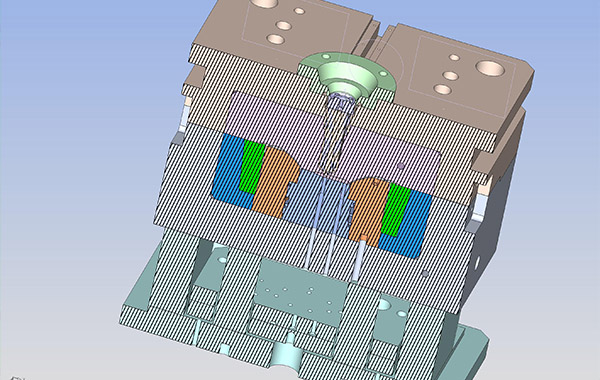

1. How we design thermoplastic injection Mold

From the estimation phase and then to the mold design phase, we support the customer through a co-engineering service that aims to obtain a product with an excellent quality / price ratio in order to meets the production needs.

From the feasibility study to the latest mold tests, each thermoplastic injection mold developed follows a quality cycle based on checks, and constant updates with the customer.

2. Molds costruction

Once the project has been developed, the production phase begins with in according to the customer specifications. Our work shop is able to produce die-casting molds with a maximum size of 1300 × 1000 and with a maximum weight of 5 tons per part.

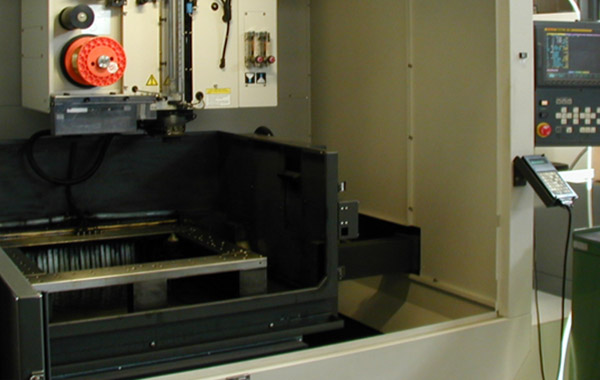

The die inserts are made on horizontal and vertical 3 and 5 axis CNC machines, each mechanical component is made independently by our tooling department.

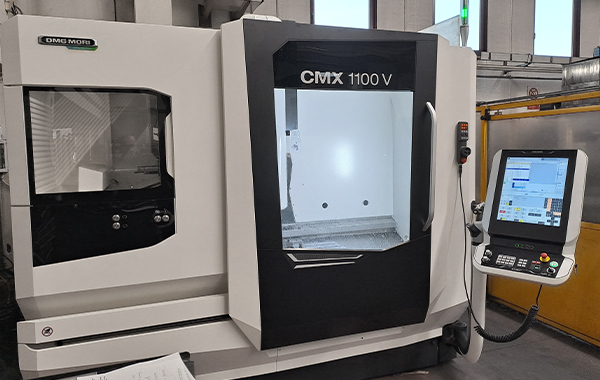

Recently the toolshop was implemented with a HS gantry milling machining able to work in roughing and finishing blocks up to 5ton with a table that reaches 1,7m x 1,3m and a latest generation DMG MORI milling machine.

3. Mold assembly

Before start the assembly phase, the assembly department checks every detail made.

Die inserts are polished and at the same time the thermoregulation lines are tested.

A pre-assembly only with a first adjustment follows. Then die inserts are put into the die holders, reconditioned or new, and then move on to the adjustment phase in the die spotting machine.

Once this phase has been passed, the components are assembled and the thermoregulation and hydraulic circuits are set up.

The mold is now ready to be sampled or delivered to the customer.

4. After sales maintenance

Our work shop is able to manage the scheduled maintenance of the equipment produced, such as the extraordinary maintenance of external molds.

We check the state of the mold with a visit from the customer and then evaluate together what kind of works do.

Our results

square meters of production area

working centers in operation

maximum weight of the molds

years of activity

Applications

With an experience of over forty years and thousands of molds made, we have become the reference point for many companies that need injection molds.